Industrial Plumbing Case Study

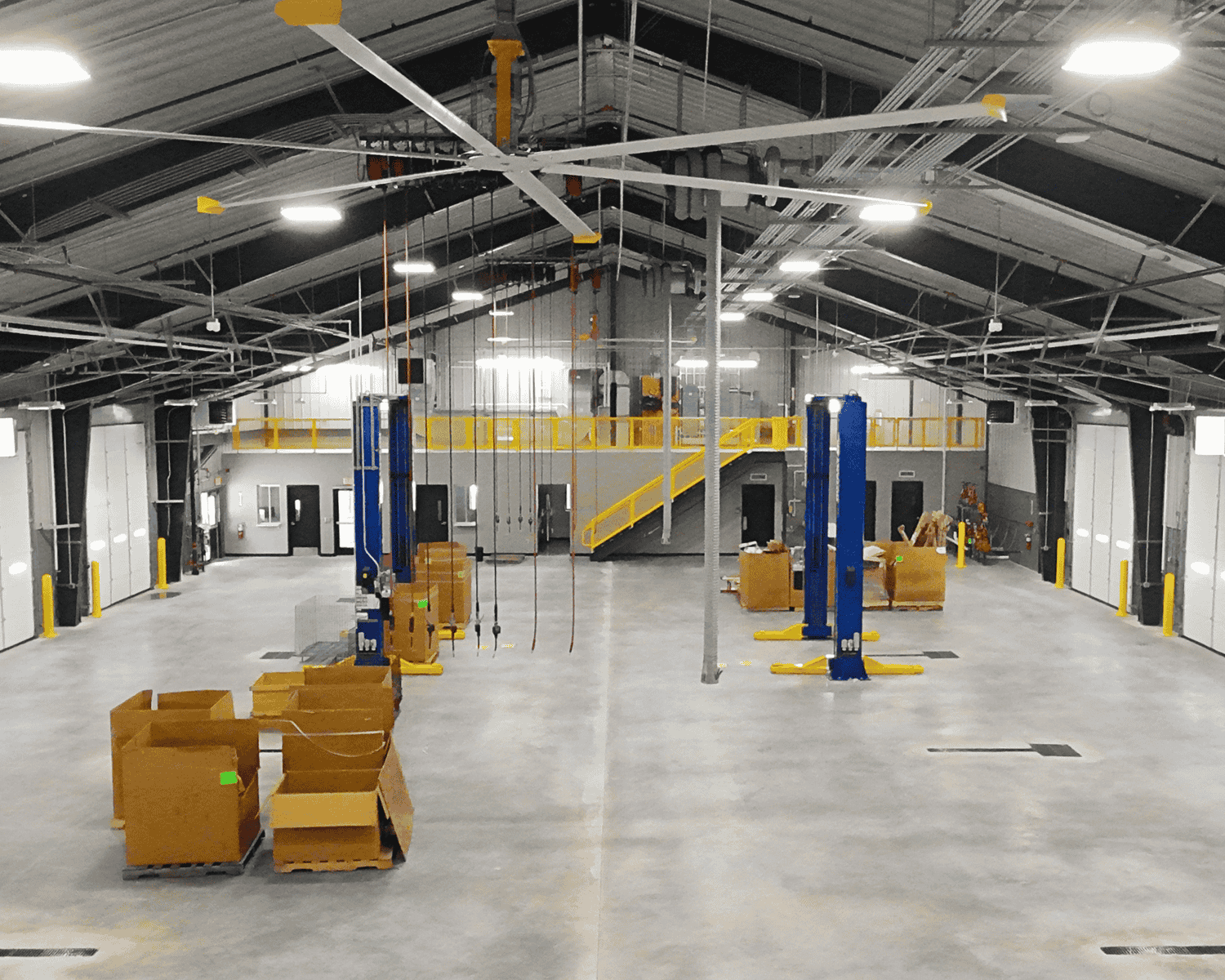

Industrial Plumbing Excellence at New River Electrical Corp.

- Project Type: Industrial Plumbing Installation

- Location: Central Ohio

- Timeline: September 2024 – May 2025 (9 months)

- Client: New River Electrical Corporation

- Facility Type: Warehouse + Heavy Vehicle Maintenance Facility

Have an industrial plumbing project that you'd like to discuss with our team?

Download the Case Study

Project Overview

Installed Systems Included:

- Sanitary drainage and vent piping (PVC)

- Domestic hot and cold water (Type L copper with ProPress fittings)

- Natural gas lines (carbon steel, both threaded and welded)

- Compressed air (galvanized threaded steel)

- Plumbing fixtures, equipment, and final air connections

Tackling a Complex Industrial Build

Clean Lines and Stronger Systems

What You’ll Notice:

- Precision-aligned overhead loops for natural gas, compressed air, and domestic water

- Multiple system drops engineered for service and repair efficiency

- Clean installation lines that are both functional and visually impressive

Outcome & Impact

What Set This Project Apart:

- Tight budget control: Change orders kept to a minimum

- No rework or failures: Systems installed level, plumb, and to code

- Durability built-in: Every connection tested, secured, and optimized for high-use industrial performance

Why It Matters

Client Results:

- Reliable service systems across both buildings

- Clear savings from minimized scope creep

- Installation that will deliver years of trouble-free operation

Lessons & Learnings:

Our Awards & Accreditations

Ohio's Most Trusted Industrial Plumbers

At Crawford Mechanical Services, we offer a full suite of industrial plumbing services tailored to meet the needs of Central Ohio facilities that include . Whether it’s preventative maintenance, repairs, or installations, our team has the expertise and tools to deliver exceptional service every time.

- 24/7 Emergency Repairs: Rapid response for issues such as burst pipes, sewer backups, water main breaks, gas leaks, and major fixture or drain failures.

- Routine Maintenance and Inspections: Scheduled checks to identify leaks, test water pressure, inspect fixtures, and prevent system failures before they escalate.

- Plumbing Installations and Upgrades: Installation of new plumbing systems, fixtures (toilets, sinks, urinals, faucets), water heaters (including tankless systems), and upgrades for building expansions or renovations.

- Drain Cleaning and Sewer Services: Clearing clogged drains, hydro-jetting, main line root removal, sewer line video inspections, and grease line cleaning to maintain proper flow and prevent blockages.

- Leak Detection and Repair: Identifying and fixing leaks in pipes, fixtures, and valves to minimize water loss and property damage.

- Water Heater Services: Repair, replacement, and maintenance of commercial water heaters, including both traditional and tankless systems.

- Backflow Prevention and Testing: Installation, testing, repair, and certification of backflow prevention devices to protect potable water supplies and ensure regulatory compliance.

- Sewer and Water Line Services: Excavation, repair, replacement, and new installation of sewer and water lines, including pipe lining and directional drilling.

- Grease Trap Services: Installation, cleaning, and maintenance of grease traps, especially for food service establishments to prevent blockages and comply with health codes.

- Gas Line Services: Installation and repair of commercial gas lines for appliances and heating systems.

- Fixture Replacement and Repair: Replacing or repairing sinks, faucets, toilets, urinals, drinking fountains, and garbage disposals.

- Preventive Maintenance Plans: Ongoing service agreements to keep plumbing systems in optimal condition, reduce downtime, and extend equipment lifespan.

- Vacuum and Pump Services: Removal of liquid waste and debris from plumbing systems, sump pump installation and maintenance to prevent flooding.

- Specialized Services: Fire hydrant installation and repair, lift station cleaning, catch basin maintenance, and stormwater system management for larger facilities.

- Compliance and Code Consulting: Ensuring all installations and repairs meet local building codes and safety regulations, including documentation and permitting as required

Protect Your Facility—Schedule Expert Maintenance Today

From scheduled maintenance to urgent repairs, Crawford Mechanical Services delivers dependable commercial plumbing solutions across Central Ohio. Our licensed professionals are dedicated to providing precise, efficient service, ensuring every facility operates at peak performance and meets the highest safety standards.

Maintain the integrity of your plumbing systems—partner with Crawford Mechanical Services for expert inspections, preventive care, and responsive support. Trust our experienced team to manage the complexities, so you experience uninterrupted comfort and compliance. Schedule your service today.